Sponsors Article

Hardware for smart factories

Large-scale equipment, centralized local deployment, abundant interfaces and protocols – features promoted by this gateway manufacturer. (Picture: Hongdian)

Smart factories are considered to be one of the most important application scenarios of 5G technology. The wireless connection of all production facilities and the further connection of design, purchasing, warehousing or logistics are essential. The Chinese manufacturer Hongdian promotes its 5G + Smart Factory solution to make the factory of the future smart.

A lot of discussions are about the smart factory and its benefits for operators. New, smart technology should strengthen information management and enhance services by using Big Data and the Internet of Things approach. One goal is formulating and arranging reasonable and effective production plans and strategies. Another key aspect of intelligent manufacturing can be predictive maintenance or prediction of machines energy consumption, e.g. In the production process of large enterprises, often involved are cross-factory and cross-region equipment maintenance, long distance source localization and other scenarios.

To provide use for operators and their decisions, smart factories need to collect and transmit more and more data. During the intelligent transformation of existing factories, it is necessary to connect the equipment in the factory such as controllers, sensors, and actuators to the network. Thus, the resulting productive environment is more complex and the number of mobile devices increases, which means that the cost of re-laying and reconstruction of the wired network deployment is high. Current Wi-Fi and 4G wireless networks are unable to meet industry production requirements of high bandwidth, low latency and large numbers of connections.

5G industrial gateway

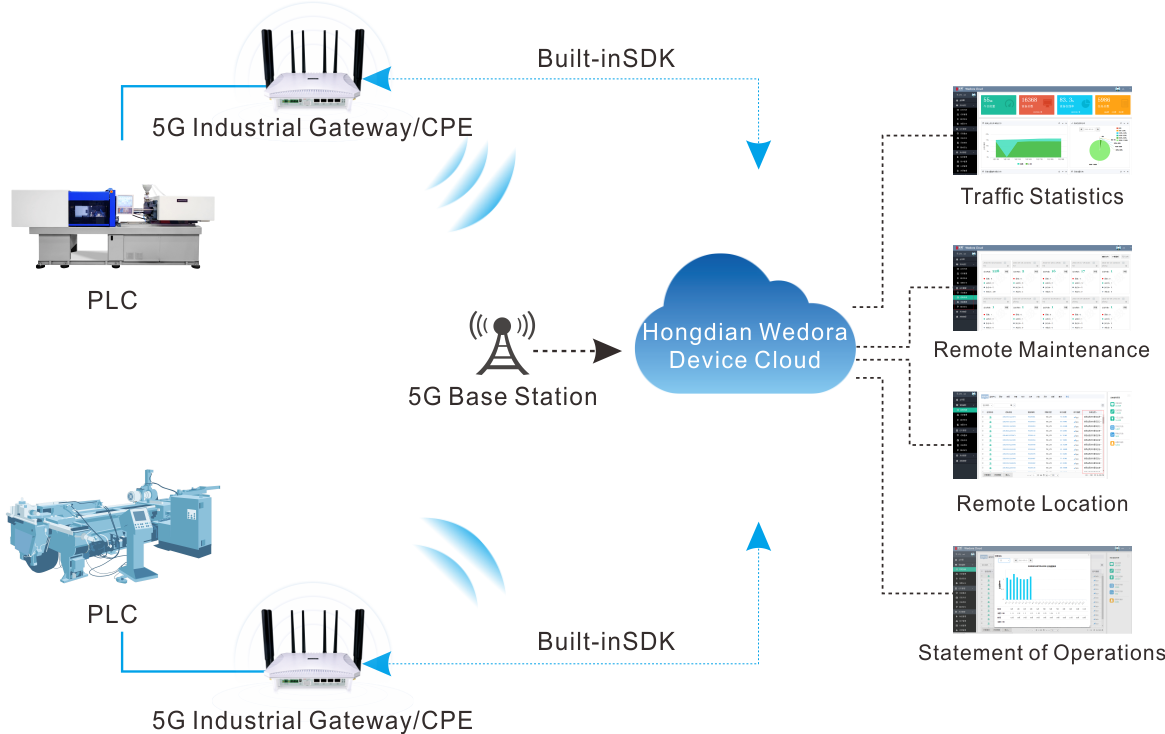

The Chinese company Hongdian proposes the 5G + smart factory solution to meet the needs of an intelligent factory upgrade. The solution connects factory equipment to provide high-performance, high-speed, high-reliability, and low-latency 5G networks for device connections, realizing real-time transmission of factory site data to the back-end operation and maintenance management platform; building a comprehensive information system centering on people and machines inside and outside the factory; Completing comprehensive upgrades of factory maintenance, allocation of productive resources and personalized production.

Hongdian offers an 5G industrial gateway that supports 5G wireless network deployment and cooperates with well-known base station manufacturers and operators in domestic and overseas, according to own statement. 5G private network has been successfully applied in many factories across China, the company states.

According to the company publications, abundant interfaces and protocols let Hongdian gateway work well under harsh industrial environments. Connecting with diverse industrial equipment, different interfaces and complex scenarios, is possible as well. The 5G industrial gateway supports wide temperature and pressure ranges, and also has external waterproof sleeve. Moreover, the resistance to strong electromagnetic interference has been confirmed by high reliability tests. It also supports various industrial protocols such as modbus and CNC, effectively accessing to PLC, industrial sensors, controllers and other equipment, and being compatible with multiple RJ45 Gigabyte Ethernet ports, RS232 / RS485 / USB / WiFi, etc. (As soon, as our editorial staff had chance to check product details, you’ll find this product in our overview 5G router for the industry.)

AGV for intelligent logistics

In the case of an intelligent logistics system for unmanned vehicles (AGV), Hongdian 5G industrial gateway equipment was applied. The hardware is designed for industrial vehicle standards, in particular, 5G networking is used to support data transmission from mobile, Unicom, telecom and other networks, while meeting private network communication requirements to meet user expectations for real-time wireless communication network and low-latency data transmission. To ensure data security, 5G devices use the built-in CA encryption authentication algorithm and are compatible with industrial protocols and custom protocol development. Combined with Hongdian’s cloud management platform function, 5G industrial gateway devices can display the actual operation of 5G devices in real time, implement remote upgrades, data configuration and other functions for online devices, display the operating status of devices and export for recording, the company describes the benefits in a special application.

Cooperation and interconnection

The 5G network connects sensors and processors on the production site, so that the robots can communicate with each other to achieve more functions and complex tasks; point-to-point communication of devices are able to access to Hongdian Wedora cloud management platform, connecting with multi-factory collaboration horizontally and supply chain interconnection vertically. Regarding to factory’s private network environment, in order to ensure that the data does not leave the factory, so the cloud platform can be deployed on the client server to achieve centralized management, monitoring and maintenance of factory terminal equipment.