Sponsor article

Designers and engineers working with 5G broadband devices need tailored, fast and cost-effective solutions to ensure the reliability of new chip designs. Learn more about the major challenges of testing 5G broadband ICs and how to overcome them.

1. The signal types are wider and more complex.

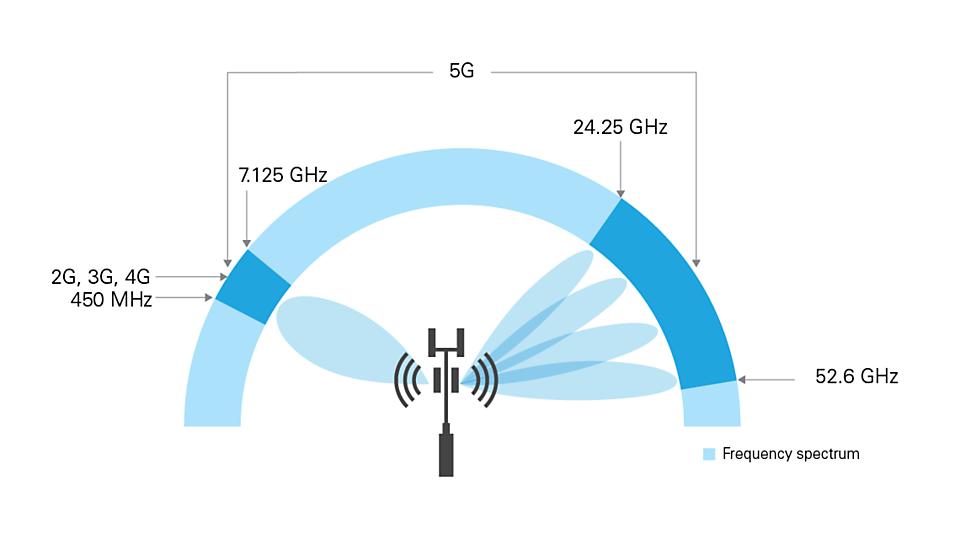

5G New Radio includes two different types of signal types:

- Orthogonal frequency multiplexing with cyclic prefix (CP-OFDM) for downlink and uplink.

- OFDM with discrete Fourier transform (DFT-S-OFDM) only for uplink. This signal form is similar to the frequency division multiplexing with single carriers (SC-FDMA) for LTE.

Researchers and engineers testing 5G devices face new challenges in the creation, distribution and generation of 5G waveforms in their test beds. Engineers must work with highly complex, standards-compliant uplink and downlink signals that have greater bandwidths than ever before. They include a variety of different resource allocations, modulation and coding sets, demodulation, sounding and phase alignment information, as well as single-carrier and carrier-aggregated configurations where individual channels are adjacent or have frequency gaps.

2. Measurement equipment must be broadband-capable and linear, and must cover a wide frequency range cost-effectively.

Although radio frequency engineers work with specialized and expensive millimeter-wave inspection systems in industries such as aerospace and defense, this is still uncharted territory for the mass market semiconductor industry. Engineers need cost-effective test equipment to configure more test stands for a shorter time to market. In addition to high linearity, these new test stands must support tight amplitude and phase accuracy across wide bandwidths, low phase noise, extensive frequency coverage for multi-band devices, and tests for coexistence with other radio standards. Together with powerful hardware, modular, software-based test and measurement stands can be quickly adapted to new test requirements.

3. The characterization and validation of components requires more intense testing.

To work with wide signals below 6 GHz and mm-wave frequencies, it is necessary to characterize and validate the performance of RF communication components. Engineers must not only test innovative designs for multiband power amplifiers, low noise amplifiers, duplexers, mixers and filters, but also ensure that new and improved radio frequency signal chains support the simultaneous operation of 4G and 5G technologies. To avoid greater propagation losses, 5G millimeter waves require additional beamforming subsystems and antenna arrays, which then require fast and reliable multi-channel test solutions.

4. Due to the radio tests of Massive-MIMO- and Beamforming systems, conventional measurements are dependent on space.

Engineers working on 5G beamforming equipment face the challenge of characterizing transmit and receive paths and improving reciprocity for TX and RX. For example, when the transmit power amplifier starts compression, it introduces amplitude, phase shifts and other thermal effects that the LNA in the receiver path would not produce. In addition, the tolerances of phase shifters, variable attenuators, regulated amplifiers, and other devices can cause uneven phase shifts between channels, which affects the expected directional characteristics. The measurement of these effects requires over-the-air test procedures where conventional measurements such as TxP, EVM, ACLR and sensitivity are dependent on space.

5. Series production tests require fast and efficient scaling.

New 5G applications and industries will exponentially increase the number of 5G components and devices that manufacturers must produce each year. Manufacturers face the challenge of providing rapid calibration capabilities for the various high frequency paths and antenna configurations of new devices and accelerating OTA solutions to provide reliable and repeatable test results for manufacturing. However, in mass production of RFICs, traditional RF chambers can take up much of the production floor space, disrupt material handling processes and multiply investment costs. OTA-enabled IC sockets – small RF packages with integrated antenna – are now commercially available. They offer functions for OTA semiconductor testing in a reduced form factor.

Leave A Comment