The joint study by Nokia and EY shows that beyond the colorful gamer worlds, the metaverse also offers real added value to industry. Enormous increases in efficiency in practice often exceed expectations, according to one of the study’s findings. This also makes it worthwhile to invest in high-performance infrastructure, such as 5G campus networks.

In the public perception, the topic of the metaverse is determined by corporations such as Meta and Co. Accordingly, the focus is on consumer topics, with avatars and virtual worlds for games and social media. So, is the metaverse just a gimmick?

No, that impression would be wrong. In fact, the metaverse has also arrived in the corporate environment and has given rise to quite interesting applications there. Nokia and the management consultancy EY have examined these aspects in a study entitled “Metaverse@Work” and have summarized in a report on the study what companies from different industrial sectors can achieve with this technology.

Fundamentally, the industrial metaverse is about a physical-digital fusion and expansion of human perception for industrial applications. It includes digital representations of physical industrial environments, systems, processes, facilities, and spaces that can be controlled, monitored, and interactively used by users.

Next step in digitalization

Based on this definition, critics might believe that the industrial metaverse is the linking of dashboards with Extended Reality (XR), i.e. Augmented Reality (AR) and/or Virtual Reality (VR). But even that falls far short of the mark. The mapping of reality as a digital twin goes much deeper – all the way to a 24/7 live view of the physical world, including the logical mapping of process chains and the associated data. Stefan Kindt, Technology Evangelist Nokia, makes it clear what this means for companies:

“Where previously it was only possible to carry out investigations on the basis of stored data with a greater time offset, live simulations are now possible – for example for training purposes or for optimisation measures – which can then be implemented very quickly in reality.”

Concrete benefits of the Metaverse

An example from the transport sector shows how the metaverse can be used profitably. The engineering firm SMEC was involved in a tunnel project in Australia, in which a river crossing was intended to improve the flow of traffic. After commissioning, it became apparent that there were still problems. An aspect of human behaviour was identified as the cause: when the road rose again after crossing the lowest point of the underpass, drivers slowed down, which led to the formation of traffic jams. With the support of the metaverse, various measures were tested via simulation to mitigate this effect and improve traffic flow.

In this way, a solution could be found that has now proven itself in reality. The operators retrofitted LED strips to the tunnel walls, which can be used to display moving points – at the optimum speed. In fact, the drivers adapt their driving style to the visual signals and accelerate a little more on the uphill section in order to stay in sync with the light signals. Now traffic is flowing smoothly again, without unnecessary traffic jams.

Already widely used

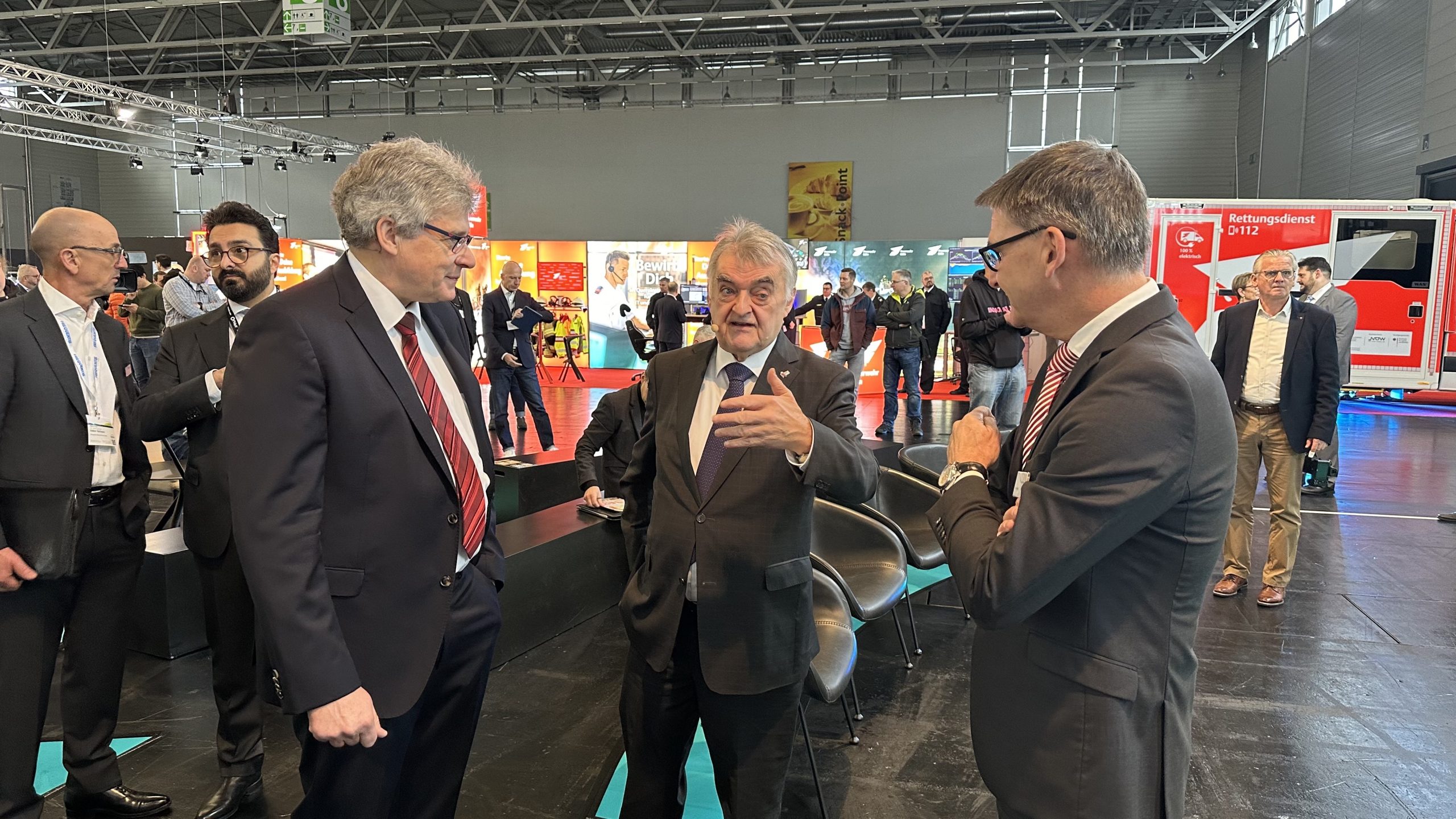

For the metaverse study by Nokia and EY (free download here), 860 decision-makers in the US, Brazil, UK, Germany, Japan and South Korea were surveyed in four key industries:

- Automobile,

- Industrial Goods & Manufacturing,

- transport, supply chains and logistics, as well as

- Energy & Utilities.

In addition, 22 in-depth interviews were conducted with metaverse experts and industry leaders, with representatives from the public safety and defense sectors in addition to the aforementioned industries.

In this way, the key drivers, benefits, challenges, and risks associated with deploying use cases in the metaverse were identified. But there are also other factors, such as enablers and partnerships, that are needed to drive value.

Added value in practice

One of the most surprising findings of the Nokia-EY study is that companies that already have industrial or enterprise metaverse applications in use rate the technology more positively than those that are still in the process of adoption. This means that the results in practice often exceed expectations.

As has been shown, a persistent overlaying of the physical world with the virtual world – and this is precisely the essence of the metaverse – creates significantly more use cases than expected at the time of conception, and thus better productivity than the profitability calculations were based on. Stefan Kindt is therefore certain that the industrial metaverse will play an even greater role in improving the efficiency of industrial plants in the future. In the next five to six years, the industrial metaverse will be a key driver for the development of the technologies needed, Kindt said.

Adapting infrastructure with 5G

However, this also means greater demands on the performance of data communication and IT resources. Real-time transmission of process data and timely analysis, the use of AI and visualization technologies on OT-related edge servers will continue to increase as the metaverse adoption. All of this will increase data throughput by around 50 percent in the coming years, according to the market experts’ forecast.

One way to cope with this growth is 5G. Own campus networks in production and on the company premises as a reliable, secure and high-performance infrastructure are a key enabler of the digital transformation, which also includes the use of the industrial metaverse.

Stefan Kindt will provide practical examples from industry and logistics at the Connect2Innovate event, which will take place in Würzburg on 22 and 23 November. He will present examples of how Nokia benefits from this in its own production, as well as some of the solutions that the manufacturer has developed for customers. The full topic list can be found on the event website https://fuenf-g.de/connect2innovate/.

Leave A Comment