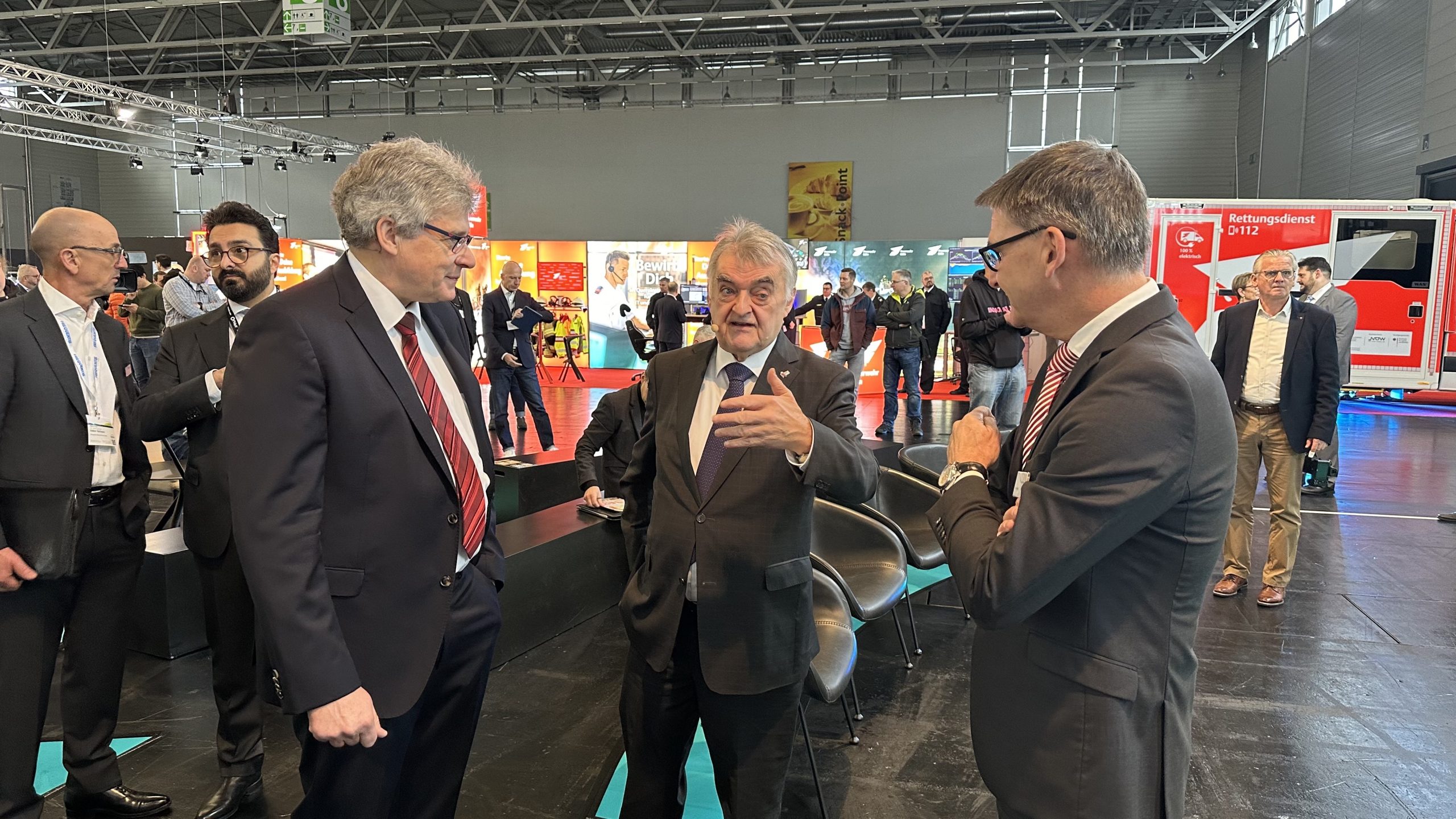

Audi and Ericsson present another pilot project for 5G in production (Picture: Audi Media Center)

Audi is taking the next step towards 5G in production: Together with the Swedish network supplier Ericsson, Audi is presenting a new pilot project in human-robot interaction. As one of the first cases, an automation application connected via 5G will be shown with a focus on personal safety.

The use of 5G in production offers many possibilities: In order for wireless production robots and employees to work together smoothly in the future, real-time wireless communication is a prerequisite. In contrast to other wireless technologies, 5G is more reliable, reacts more robustly at high workloads and is therefore particularly suitable for connecting sensors, machines and human-operated terminals. Ericsson, together with Audi, is now presenting another example of 5G in automotive production: An industrial robot installs an airbag module in the steering wheel of an Audi.

The robot cell is protected by safety sensors. As soon as a human hand breaks through the light curtain of the cell, the robot stops automatically. The high-frequency (fieldbus) communication required for this is made possible by the very low latency, i.e. an end-to-end delay of about one millisecond. Thanks to 5G technology, interaction between man and machine is now also possible by wireless means. “5G connects all points in our production environment, which leads to enormous improvements in flexibility and connectivity, as well as showing what secure human-robot interaction can look like,” says Arjen Kreis, Head of Body Shop Automation Technology Audi Neckarsulm.

“As part of our 2018 announced project with Ericsson, we are testing the possibilities of 5G technology for industrial applications in the smart factory in the Audi Production Lab. With these projects, we will learn more about how wireless networks can be optimally used in a Smart Factory,” says Dr. Henning Löser, head of the Audi Production Lab, in which industrial application scenarios for automobile production based on 5G are tested and further developed. Together with Ericsson, Audi is focusing on a particularly latency-critical application, such as interaction with an industrial robot.

Since 2018, the premium car manufacturer Audi has been working with the Swedish telecommunications group Ericsson to test the use of 5G mobile and network technology for the production of vehicles. The partnership between the car manufacturer and the 5G innovation leader offers the opportunity to recognize the potential of wireless communication in production at an early stage. “5G offers the extremely low latency that meets the performance requirements of industrial automation,” explains Marie Hogan, Head of Mobile Broadband & IoT at Ericsson. “Advanced use cases and system-critical IoT networking combined with the benefits of greater flexibility, mobility and efficiency for production automation are now possible. The ‘cutting of the cables’ is the real turning point in the Industry 4.0 era”.

Leave A Comment