Arburg’s 5G Campus network joined Deutsche Telekom as a pilot customer during the Technology Days 2022. (Image: Arburg)

A leap forward for the mechanical engineering world: Arburg, a manufacturer of injection moulding machines for plastics processing from Baden-Württemberg, has introduced a 5G test field for networked production in plastics processing. The Deutsche Telekom 5G campus network is already in use at the company’s headquarters in Lossburg.

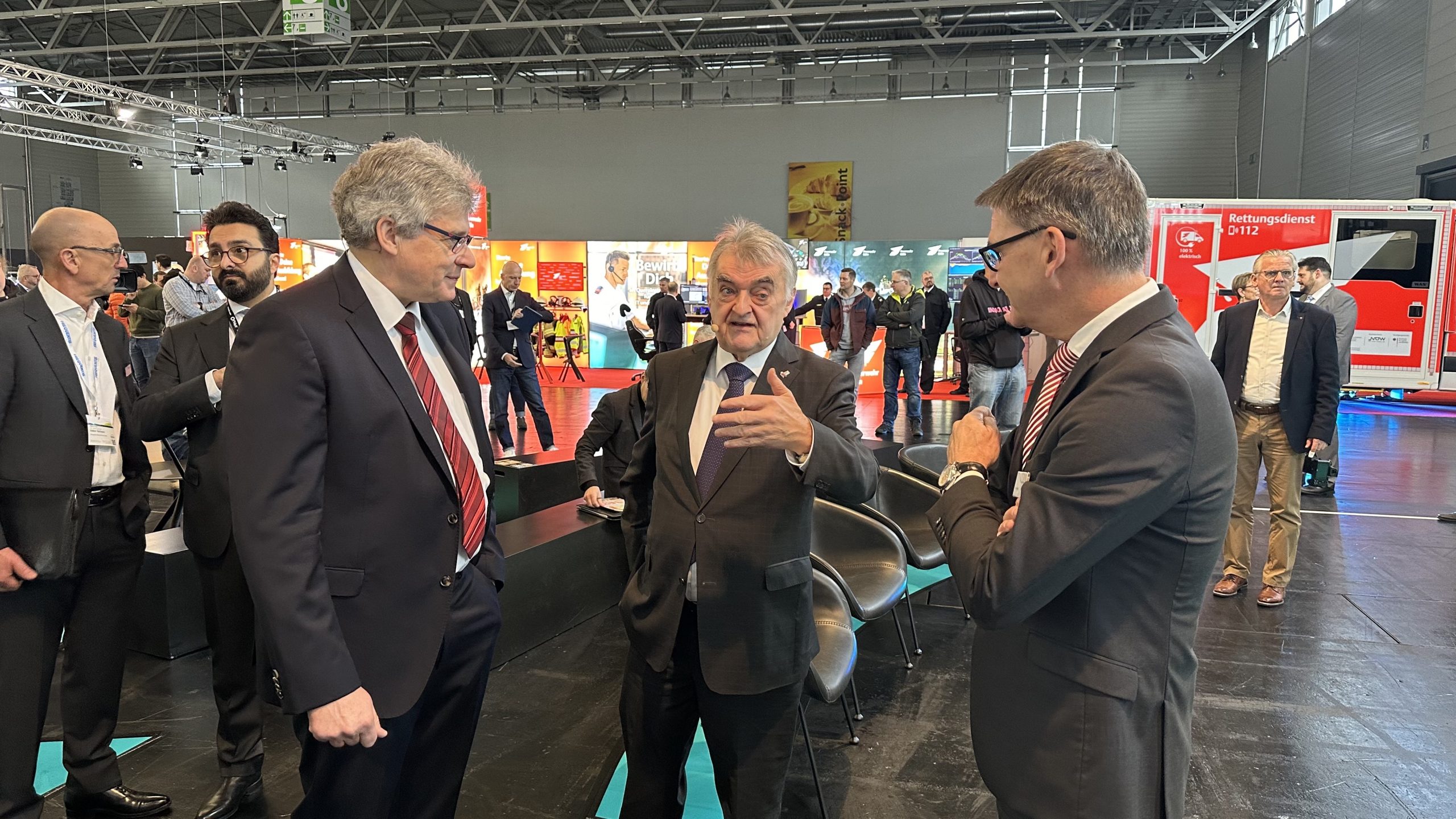

Manufacturer Arburg has put a 5G campus network from Deutsche Telekom into operation at its headquarters in Lossburg. It is intended to enable inhouse production to test innovative applications, such as autonomous transport systems, industrial robots or automated production processes. Meanwhile, its industrial customers from a wide range of plastics-processing sectors, such as the automotive and packaging industries or medical technology, have had the opportunity to test digital manufacturing concepts. The Arburg Technology Days took place from 22 to 25 June, 2022. A digital highlight was the brand-new 5G campus network, which Arburg used as a pilot customer of Deutsche Telekom at the Technology Days 2022 in the customer centre for networked manufacturing in plastics processing. For the event, Deutsche Telekom had equipped the Arburg customer centre with eight special in-house antennas that provide the 2,100 square metre area with 5G.

“With Telekom’s new 5G campus network, we have the opportunity to make our production processes more efficient and integrate them even more intelligently. Particularly in the case of widely varying batch sizes and customer-specific solutions, 5G brings new opportunities for the flexible adaptation and automation of production and logistics along the entire value chain.”

Guido Frohnhaus, Managing Director, Technology at Arburg

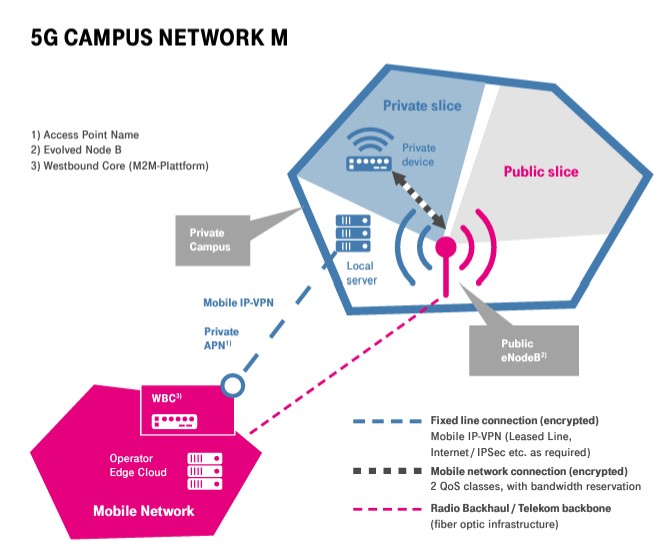

Key advantages of combining a private and public 5G network

Using 5G non-standalone, the campus network is carried in the 3.6 GHz frequency range. It combines the strengths of Telekom’s public 5G network with the exclusivity of a virtual private network. As far as the manufacturer is concerned, this offers the advantage of ensuring optimal and stable coverage via the public 5G network. Furthermore, the business-critical data traffic, for example from injection moulding machines, flows separately via a virtual private network and can be prioritised. This separation of functions is intended to ensure a high level of data security and maximum reliability. Concurrently, the public 5G network enables the supply of employees, suppliers or customers and the integration of their data into the networked production process.

Upcoming 5G plans for Telekom and Arburg

What does this future partnership envisage? Telekom plans to test the new product “Campus M with industrial frequency” together with Arburg for the first time. With no additional infrastructure, the local 5G network will in the future also transmit via the industrial frequencies in the 3.7 to 3.8 GHz range allocated by the Federal Network Agency. Together with Telekom’s own core network, Arburg will thus have an additional private campus network. The latter will enable the use of exclusive SIM cards for networked devices and guarantee the full performance of the private 5G network with download speeds of up to 1GBit/s. At the same time, public 5G coverage will be fully maintained in parallel. In principle, two campus networks and a total bandwidth of around 190 MHz will be available for Arburg in years to come.

The 5G Campus Network M: Key Features

Highlights: 5G CAMPUS NETWORK M for local corporate networks

- Connection to the private campus network with Quality of Service (QoS) in the spectrum Public Slice Public eNodeB2

- Guaranteed transmission quality for demanding IoT services in the private slice

- Private APN (Access Point Name) for secure transmission of company data between the customer site and the Telekom network

- Individuell auswählbare Übertragungstechnik zwischen Telekom-Netz und Kundenstandort (z.B. MPLS, Ethernet, IPSec / Internet)

- Can be combined with an operator edge cloud for low latency

- Fibre optic connection to the entire mobile network infrastructure of the site – Improved public mobile network coverage on the company premises

Leave A Comment