In the industry, private 5G networks are on the rise. The reason? They enable companies to digitize and optimize industrial processes, leading to efficiency gains and aligning with ambitious sustainability goals. Recently, steel and mining conglomerate ArcelorMittal France, along with Orange Business and Ericsson, announced the operational launch of the 5G Steel Standalone network in Dunkirk. This represents the largest 4G/5G network in an industrial setting.

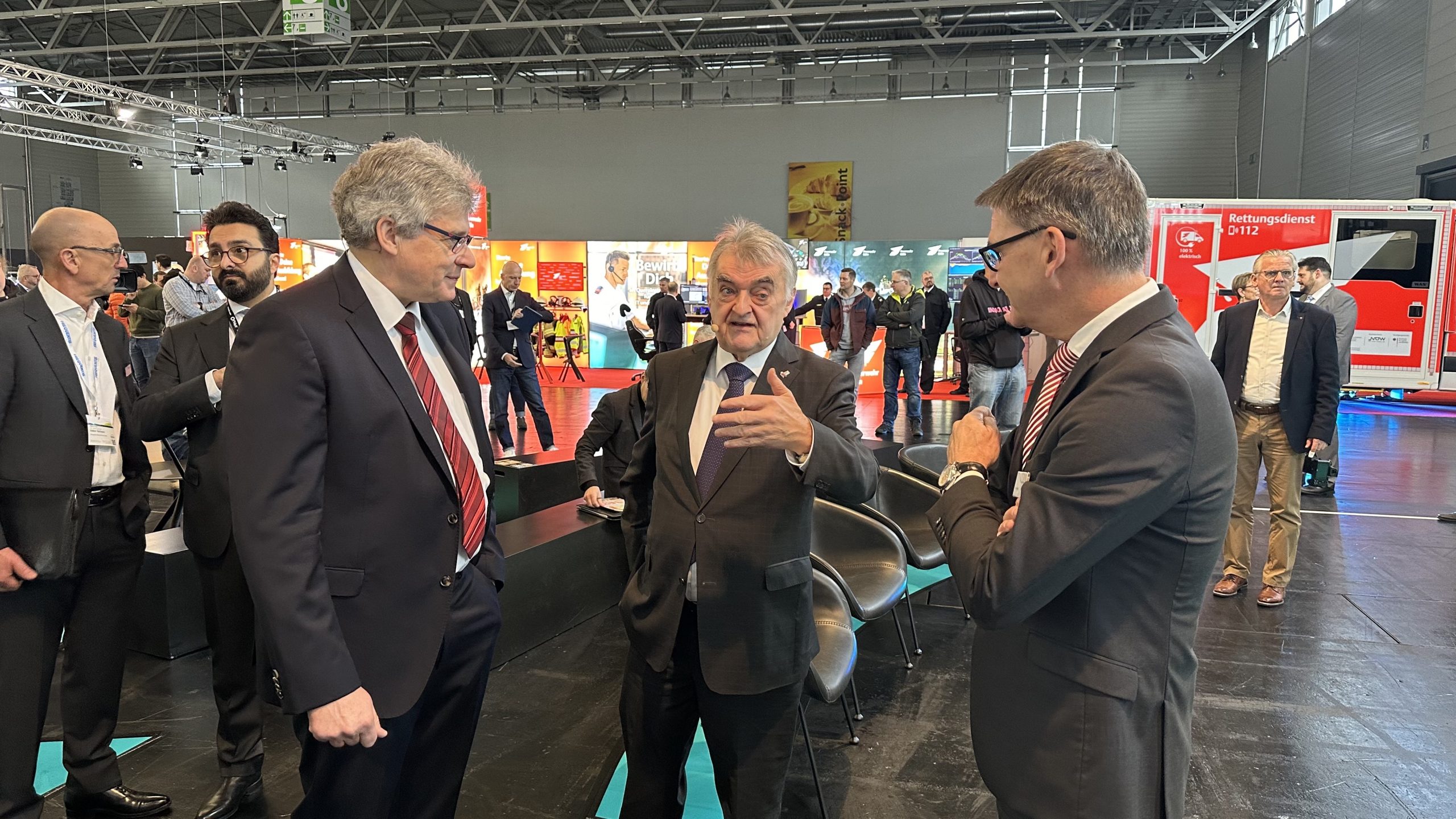

Complex Industrial Site Coverage

Private 5G networks are fast, robust, and characterized by high bandwidth and reduced millisecond-level latency. Their robustness allows for coverage of very large and complex industrial sites. In the case of ArcelorMittal in Dunkirk, this spans an area of over 40 square kilometers, encompassing open spaces, tall metal structures, and steel production halls. Reliable 5G coverage ensures seamless connectivity for employees in production facilities, providing them with increased mobility.

Streamlined Steel Recycling

ArcelorMittal harnesses high data throughput rates to optimize the steel recycling process. When steel arrives at the recycling site, it is weighed and scanned to determine its density, composition, and check for impurities or residual colors. On-site quality control personnel automatically transmit this data via 5G Steel to the production system. Remote analysis allows decision-makers to assess whether the metal is suitable for recycling. Crane and forklift operators immediately have the necessary information for upcoming actions.

Communication within work processes is also transformed by 5G Steel. For instance, in the hot strip mill, data capture, input, and exchange can be performed faster and more intuitively with tablets. This facilitates and accelerates tasks such as maintenance inspections, safety audits, and lockout/tagout procedures.

Enhanced Efficiency Reduces the CO2 Footprint

Through 5G and real-time data utilization, a company’s overall performance can be enhanced, and resources can be used more efficiently, resulting in reduced energy consumption. This is a significant advantage in the context of growing climate protection and sustainability requirements. Thus, 5G is set to play a crucial role in the future achievement of ESG goals for businesses.

Increased Workplace Safety with Autonomous Vehicles

Due to the low latency of the 5G network, autonomous driving is one of its most prominent applications. In large steel production facilities like those at ArcelorMittal, steel often needs to be transported on trains over long distances from one production step to the next. Sensors mounted at the front and rear of the train provide real-time information about events and conditions on the track, assisting train operators in making appropriate decisions.

In tight industrial settings, there is often insufficient space for train turnarounds. The locomotive is positioned at the rear of the train and pushes the freight cars forward. Since the driver cannot see what is happening in front of the first car, a second person traditionally walked ahead of the train, communicating with the locomotive operator via walkie-talkie. Sensors with edge computing capabilities provide real-time information to the locomotive operator. While the trains are not yet fully autonomous, they represent a significant improvement in safety and process efficiency.

Infobox: 5G Steel in Numbers

9 radio sites with 4×4 MIMO antennas covering Dunkirk and Mardyck sites

1 core with dynamic geographic redundancy managing up to 50,000 users

Monitoring tool for the management and operation of the 5G Steel network

19 routers from Cradlepoint, a subsidiary of Ericsson

80% of the area exceeds speed targets

Outlook

The 5G Steel initiative is supported by the French government as part of the France Relance economic recovery plan. It enables the implementation of the first industrial applications at the ArcelorMittal site in Dunkirk.

In addition to Dunkirk, 5G Steel is currently being deployed at the ArcelorMittal site in northern France, Mardyck. Throughout 2023, additional locations are planned, especially in eastern France, in Florange. Future industrial applications to be developed at ArcelorMittal sites include initiatives related to the mobility of people in work situations, autonomous rail vehicles in Dunkirk and Florange, autonomous road vehicles, the expansion of mobile maintenance with field data feedback, virtual or augmented reality, and other safety measures.

Guest Author: Emmanuel Routier, Vice President Smart Industries, Orange Business

Leave A Comment