At DMG Mori, founding initiator of Adamos, the digital twin is at the center of the paradigm shift from classic mechanical engineering to comprehensive networking of industrial manufacturing technology with data-driven information and communication technologies. (Image: DMG Mori)

The open and manufacturer-neutral IIoT platform Adamos aims to link modern IT technology and industry knowledge in mechanical engineering. Since the beginning of this year, this is also to happen in cooperation with the Open Industry 4.0 Alliance. Together, the two initiatives want to further advance the realization of open digitization platforms for the manufacturing industry.

The Industry Internet of Things (IIoT) is currently being driven forward in many companies and institutes. As the history of the Internet shows, such decentralized developments driven by entrepreneurial interests almost automatically create new system boundaries that complicate the daily lives of users. The goal of the Open Industry 4.0 Alliance (OI4) is to improve the interoperability of IIoT platforms and digital solutions and to increasingly use Industry 4.0 applications in digitally integrated global supply chains.

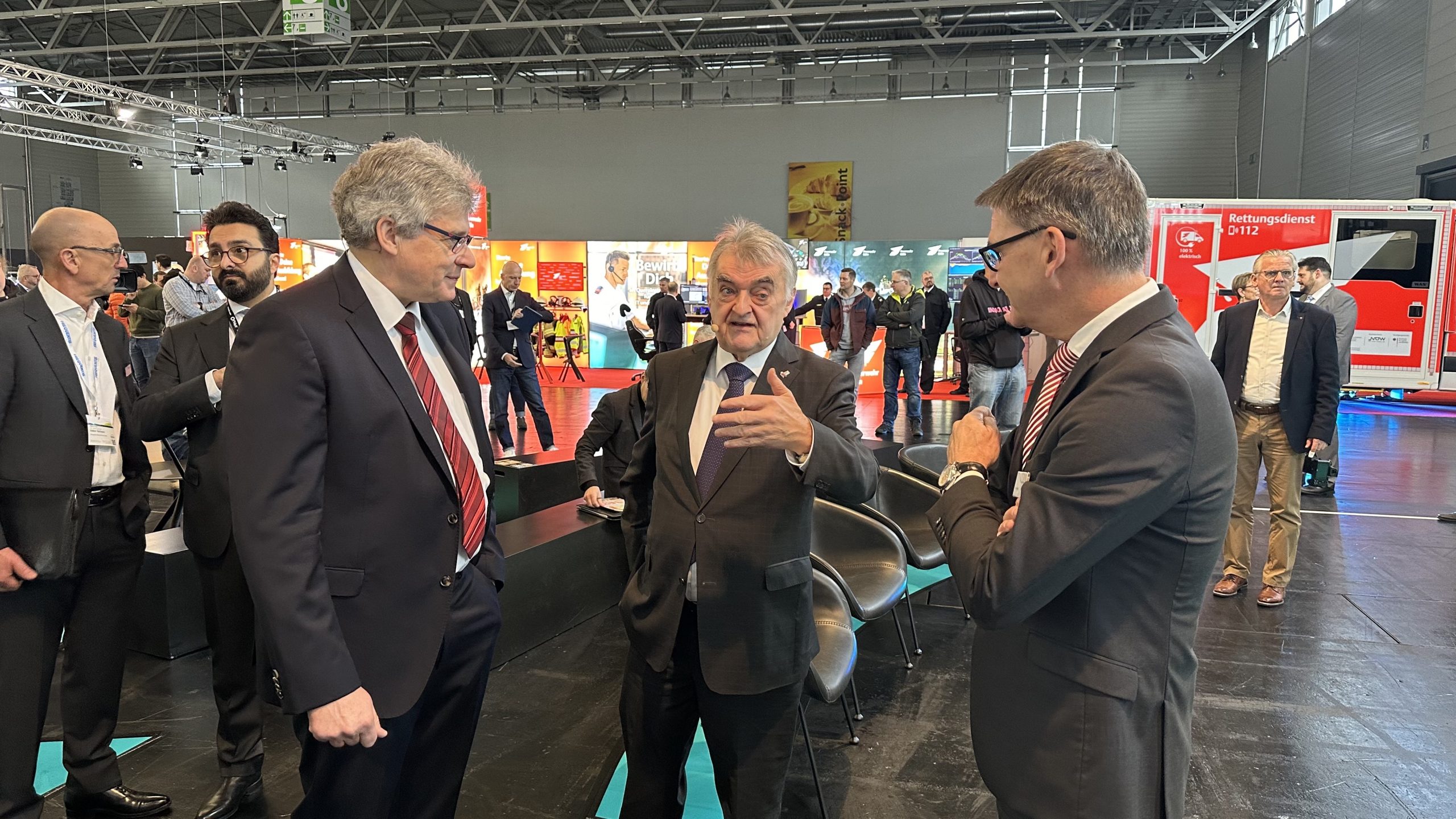

Adamos joined the Open Industry 4.0 Alliance on January 1, 2022. The alliance brings together industrial companies to work pragmatically on implementing cross-vendor Industry 4.0 solutions and services for manufacturing plants and automated warehouses. In industry and technology working groups, industry experts develop use cases and implement them technically based on the OI4 reference architecture. These solutions, together with implementation aids, are shared in the community and also made available outside the alliance.

“We will actively contribute our experience from setting up the marketplace and the connected integration platform to the working groups. This will result in a variety of synergies with the content-oriented and equally neutral principles of the Open Industry 4.0 Alliance.”

Dr. Marco Link, Managing Director of Adamos GmbH

His management colleague Dr. Tim Busse adds that both initiatives primarily address the interests of small and medium-sized companies from the production and manufacturing technology environment and offer them clear advantages when entering digitalized production. “True to the motto ‘B2B like B2C’, we offer end customers a unique customer experience. Through Adamos, customers have the opportunity to find, test, buy and use digital products in one central place – this is unique in the market and perfectly complements the initiatives of the partner companies of the Open Industry 4.0 Alliance.”

“With the membership, Adamos GmbH consistently underlines its open character, which perfectly fits our alliance. We look forward to the common future and innovative collaboration based on our open ecosystem.”

Ekrem Yigitdöl, Managing Director of the Open Industry 4.0 Alliance

As a manufacturer, DMG Mori recognized the opportunities of digitalization early on, also for its own product range. Thus, the topic was one of the focal points last fall: Development of flexibly automated manufacturing systems on Digital Engineering and Digital Twins. From the company’s point of view, industrial digitalization marks a paradigm shift from classic multi-stage manufacturing to comprehensive networking of industrial productions with information and communication technology. In this change, the company sees “immense opportunities to digitally refine and holistically accelerate its own transformation from a product manufacturer to a provider of customer-oriented product service systems”.

Background

Adamos GmbH

In 2017, the companies DMG Mori, Dürr, Software AG, Zeiss as well as ASM PT founded a strategic alliance for the future topics “Industry 4.0” and “Industrial Internet of Things” (IIoT). The joint venture Adamos (ADAptive Manufacturing Open Solutions) has been founded as an open and manufacturer-neutral IIoT platform. The jointly developed software platform has been available worldwide since October 1, 2017.

Leave A Comment